If I wanted a rotating camera, there was a video for that as well. If I needed a hose, I'd find a video on creating hoses.

If I needed a chrome bottle, I'd research Youtube for a blender project that created a chrome bottle. I realized that I didn't need to understand all of Blender, only the parts that I would need to create my project.Įach part and piece became a different tutorial. Initially, I was overwhelmed trying to learn as much as I could about Blender's workings and was near quitting until I had a bit of a revelation.

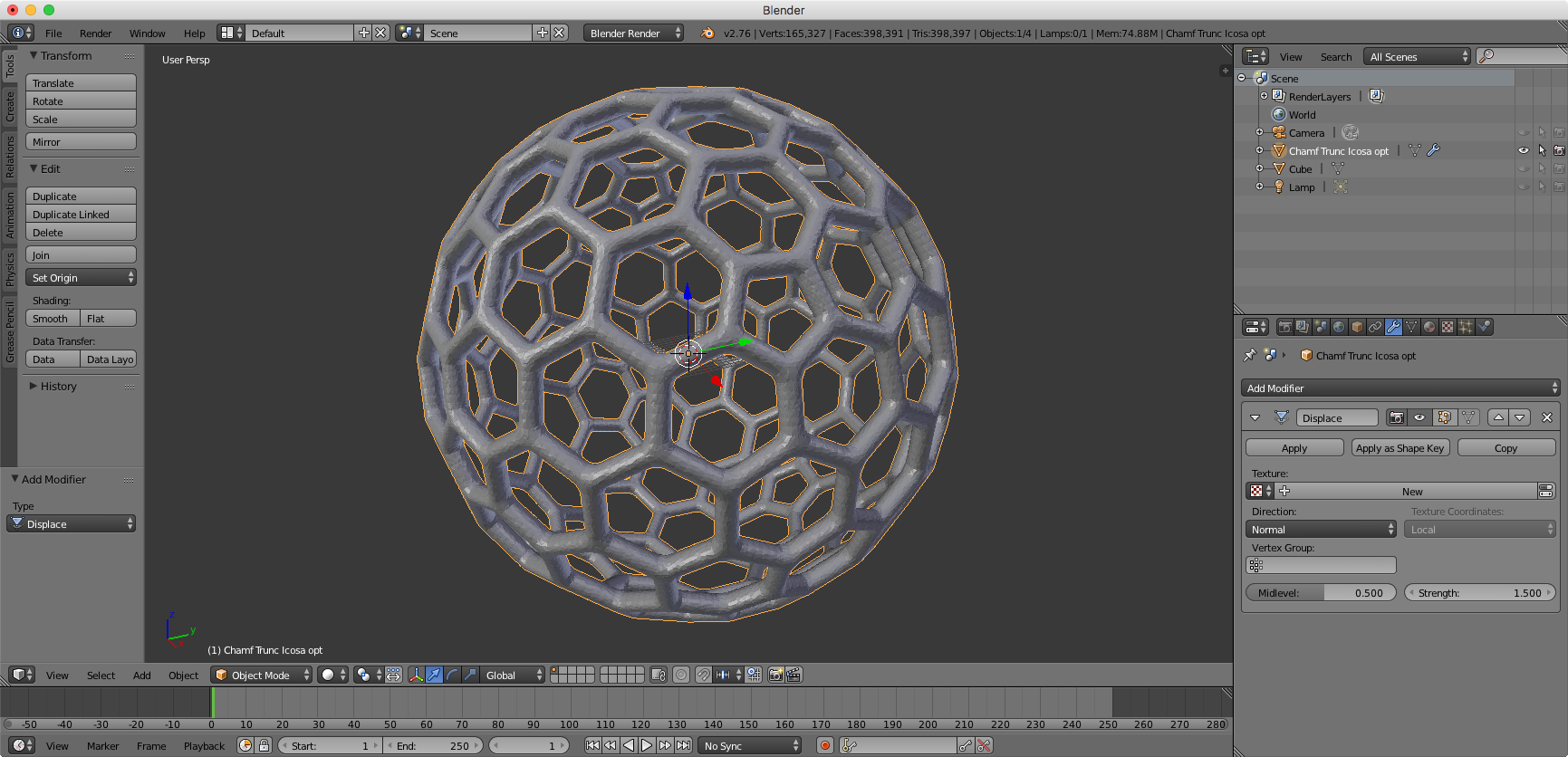

BLENDER 3D DESIGN SOFTWARE

The learning curve, for a new piece of software can be pretty steep, especially when you're learning to manipulate objects in a 3D environment. Parts I can't find, or purchase locally I'll build, but plan for their commercially manufactured part in the final design.

If I need a hose, I'll get 6 different hoses. Essentially, by the time construction happens I've picked multiples of each projected piece.

As a process, I tend to gather parts, needed or not, into huge bins for potential use. This is the third prototype I've created, and easily the most complex. It's particularly useful in that it doesn't tie you down to one computer, allowing you to work on it anywhere you may be, while affording you the ability to show anyone your project on the fly. This is a huge advantage since you can edit your design on the fly, and upload it to the cloud, accessing it from any device.

BLENDER 3D DESIGN UPDATE

Yes.I DO use windows paint, but for the reason that its relatively simple to use and and can give you a quick hardcopy of the design in your mind.Īn update to that, is to use Autodesk Sketchbook, which is available in the Google Play Store and the App Store. Traditionally, before I start a project I've always drawn it out in Windows Paint. Step 1, as always is knowing what you want to build. You need a way to test form and function and to ensure that parts will fit where you want them to fit without having to shoehorn them into place because of bad planning, ruining the overall form and severely altering your imagined design. You may have a vision in your mind, but the reality is that a real world application of your design may not be feasible, especially if your working prototype doesn't bear a resemblance to your envisioned product. When you're prototyping a potential marketable product, it can be difficult if you don't have the facilities or resources to create your finished design. I had a lot of work ahead of me, so with that, I set to prototyping. Finally, It needed to be comfortable, incorporating a pistol shape for rough work, and pen shaped for fine detail, allowing for a greater range of movement. This meant designing it with external parts that could be removed or replaced without the use of special tools or technical knowledge. I also wanted to make it modular, in that it could be upgraded or repaired without any mechanical skill. When I first created the instructable, I was simply trying to create a cost effective version of a different tool, but as I progressed, I saw that there was serious room for improvement in the design, to give it more control and functionality as well as aesthetics. It's based on an instructable for a glass etching tool, that I'd created some time ago. This is a project I've been working on is called the U.S.C.Etch (pronounced you-sketch) which is short for Universal Surface Compound Etcher, and is a tool designed to etch on any surface using chemical free, micro abrasive etchant.

0 kommentar(er)

0 kommentar(er)